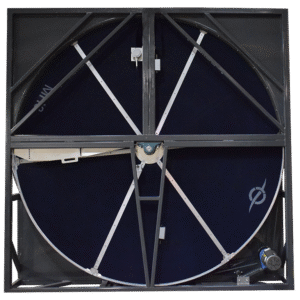

Thermowheel Rotor

The rotor system for all our wheels is made up of three main components: hub and bearing, spokes and rim. Our media is always segmented

and supported by spokes, tensioned in place by the rim.

TF & TR Series Patented Rim & Spoke Design

This unique design allows each section of the wheel to be tensioned independently thus simplifying field assembly and assures a flatter, rounder, stronger wheel. Spokes are engineered for strength and precision-fit of media segments. Rims have V-shaped grooves on the outside to keep belts in place and ridges on the inside perimeter to secure the media in place.

Rugged Hub & Bearing Assembly

The foundation on which the wheel is built. Each hub shaft is machined to strict bearing manufacturer’s tolerances to allow for a precise fit and zero movement between the rotor hub and the bearing. Each wheel uses taper roller bearings with a minimum L-10 life of 1,000,000 hours.

Secure Seals

Thermowheel Labyrinth seals are strong and flexible, yet stay firmly in place. They can be set to 1/32” clearance from the media face because the I-beam spokes feature almost zero deflection. The Labyrinth design uses differential pressure to create eddy currents on the tip of the seal

to prevent air leakage.

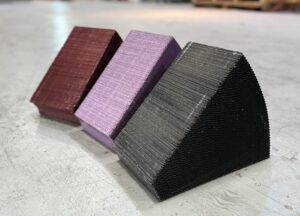

Media

We offer enthalpy, sensible, passive and active dehumidification media. Our enthalpy media used for latent moisture and sensible heat transfer, has a balanced sieve 3Å molecular desiccant coating on aluminum foil. Our sensible media used for sensible heat transfer only, has an anti-corrosion epoxy coating on aluminum foil. Our passive and active dehumidification media is for moisture removal applications. Our passive dehumidification media has a Type III desiccant coating on aluminum foil and our active dehumidification media is corrugated fiberglass with an “in situation” formed silica gel desiccant.

Motor Drive System

We offer belt and direct drive options. Our direct drive option is available with the gear reducer connected to the rotor’s hub extended shaft via a keyway. Our belt design features a simple gravity tensioned double ”V” belt design.

Control System & Sensors

Our control system provides proper operation of the energy recovery wheel in all conditions and environments. The ETL Listed, UL 508A Approved

Control Panel is Enclosed in A NEMA 4 Cabinet.